TEL:400-0033-603

Anhui BEQ Equipment Technology Co., Ltd

Hefei Baisi New Materials Research Institute

Hefei Oulai Di Optoelectronics Technology Co., Ltd

Copyright 2017 Anhui BEQ Equipment Technology Co., Ltd. 皖ICP备12002778号-1 Powered by: www.300.cn

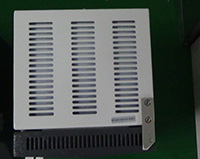

(MF-1100C-L)/1100℃ 64L Muffle furnace

Main Features

Used in Lab as material sintering furnace, annealing furnace, smelting furnace, dental furnace, etc.

It is possible to add a vent to be used as Nitrogen protection furnace, Argon protection furnace, Oxidizing furnace, Carbonizing furnace.

A general necessary electric furnace for experiment in Lab.

Technical Parameters

|

|

|

||||||||

|

Power |

Power rated: 6KW (220V) |

||||||||

|

Voltage |

Voltage rated: AC 220V 50/60HZ |

||||||||

|

Furnace Construction 炉子结构

|

High purity fibrous alumina insulation for maximum energy saving - 30% less power consumption than other brands

The spring door buckle is used to solve the contraction gap caused by high temperature in the chamber of the equipment.

|

||||||||

|

Working Temperature

|

Max. Temperature: 1100℃ Continuous working temperature: ≤1000℃ Recommended Heating Rate: 5-40℃/min |

||||||||

|

Max. heating rate |

10℃/min |

||||||||

|

|

PID automatic control and auto-tune function. 30 programmable segments for precise thermal processing. Built-in protection for the over-heated and broken thermocouple. |

||||||||

|

Thermocouple |

K type |

||||||||

|

Heating Elements |

Fe-Cr-Al Alloy doped by Mo |

||||||||

|

Temperature Accuracy |

+/- 1℃ |

||||||||

|

Dimensions

|

Chamber size(L*D*H): 400*400*400mm (64L) Furnace size(L*W*H): 650*620*940mm |

||||||||

|

Net Weight |

115kg |

||||||||

|

Packing dimensions(L*W*H) |

690*660*1000mm(wooden case) |

||||||||

|

Shipping weight |

170kg |

||||||||

|

Warranty |

1 year limited warranty with lifetime support (Such consumable parts as resistance wire are NOT supported by the warranty) |

||||||||

|

Attention

|

The equipment is not sealed, and can not be put into toxic, harmful, inflammable and explosive gas. Can add the inlet port to pass through the inert gas or oxygen. Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating. You shall place the sample in to a crucible. Never place sample on the chamber bottom directly. |

||||||||

|

Compliance |

CE Certified |

||||||||

|

accessories |

|