TEL:400-0033-603

Anhui BEQ Equipment Technology Co., Ltd

Hefei Baisi New Materials Research Institute

Hefei Oulai Di Optoelectronics Technology Co., Ltd

Copyright 2017 Anhui BEQ Equipment Technology Co., Ltd. 皖ICP备12002778号-1 Powered by: www.300.cn

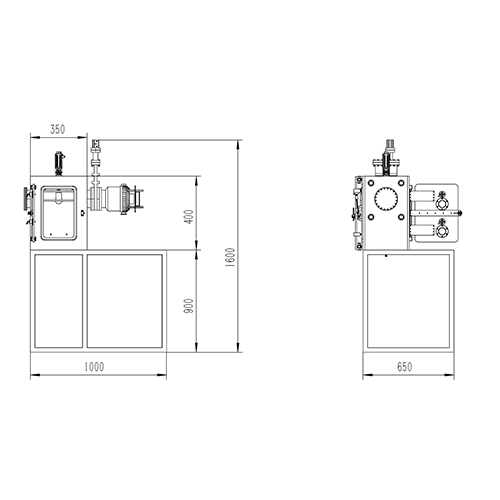

BZD-300 Multi-source evaporation coating system

一、System function and structure

1. The system is a multi-source evaporation coating system. The system can be used to develop nano-scale single-layer and multi-layer functional and composite films. The system is mainly composed of a coating chamber, a metal evaporation source (2 independent sets, with power supply), a rotating sample stage, a molecular pump set, a vacuum measurement system, a film thickness gauge, a gas path system, and an electronic control system.

2. Coating ultimate vacuum:≤10-5 Pa

Vacuum is obtained by molecular pump (1200L / S) and mechanical pump (8L / S) + CF200 main valve. This configuration has fast pumping speed, high vacuum environment can be obtained, and the cleanliness of the film can be provided.

The condensing filter well is equipped in front of the vacuum pump group, and the vacuum system is contaminated by the evaporation material.

3. The coating chamber is equipped with two sets of thermal evaporation sources, distributed on a circle (the bottom cover is evenly distributed), each source can work independently / sequentially, equipped with a circular rotating baffle, to which work does the baffle gap move Position, which station material can evaporate.

4. The sample table is arranged in the upper part of the vacuum chamber, and a maximum of 6 inches of sample can be placed. The sample has a continuous rotation function, and the rotation is continuously adjustable from 0 to 30 rpm.

5. Vacuum measurement adopts imported INFICON full range gauge for measurement.

6. The system is equipped with a two-way domestic port MFC control air intake system with a flow rate of 100SCCM and 50SCCM respectively.

7. equipped with an INFICON film thickness gauge.

二、main parts and specifcation

Sputter chamber ultimate vacuum:≤10-6Pa

System vacuum leak detection rate:≤5.0x10-8Pa.l/S;

The system starts pumping from the atmosphere: the sputtering chamber can reach 5x10-4 Pa in 35 minutes;

1、Sputter chamber

The vacuum chamber has a square front door structure with a size of 350mmx400mmx350mm (width X height X depth) all stainless steel structure. It can be baked up to 100 ~ 150 ℃, made of stainless steel, argon arc welding, the surface is electrochemically polished, the first domestic passivation treatment, the interface is sealed with metal gasket or fluorine rubber ring; manual front door opening structure; evaporation source installation On the lower cover plate, the substrate turntable is on the top, and the optical fiber rotating device is provided on the left side.

2、two sets of Coating source

3、Rotating substrate stage

3.1 Substrate size and quantity: 6 inch samples are placed 1 piece at a time.

3.2、The revolution of the substrate is driven by a speed-regulating motor, continuously adjustable from 0 to 30 rpm, and the rotation speed

4、gas

4.1、100SCCM、50SCCM MFC

5、Extraction unit and valve, pipeline

5.1、Molecular pump;

5.2、Mechanical pump:;

5.3、DN40Electric globe valve;

5.4、Side pumping pipeline between mechanical pump and vacuum chamber

5.5、CC200Pneumatic gate valve