TEL:400-0033-603

Anhui BEQ Equipment Technology Co., Ltd

Hefei Baisi New Materials Research Institute

Hefei Oulai Di Optoelectronics Technology Co., Ltd

Copyright 2017 Anhui BEQ Equipment Technology Co., Ltd. 皖ICP备12002778号-1 Powered by: www.300.cn

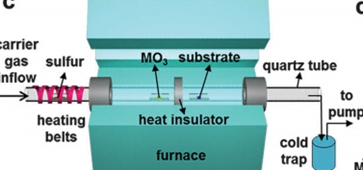

Front-end preheating molybdenum sulfide preparation equipment

main feature

The front end is equipped with a preheater that can be heated to 400 ° C to assist sulfur powder evaporation, and the rear end is a dual-temperature zone vulcanization furnace. The temperature control is accurate and the operation is simple. It is also equipped with an atmosphere fine-tuning device, which can accurately reflect the gas pressure inside the reaction chamber. The adjustment valve with scale is very practical for low pressure CVD and has good repeatability.

technical parameter

|

Sulfur powder preheater

|

model:BTF-400C

working temp.:350℃

max. temp.:400℃

max. heating rate:30℃/min

suggested heating rate:10℃/min

temp. control:30 programmable segments for precise thermal processing

voltage:AC220 V

power:800W

temp. accuracy:±1℃

heating element:· Resistance wire, Fe-Cr-Al Alloy doped by Mo

|

|

Vulcanization furnace

|

power(KW):3

voltage(V):AC220v 50/60 Hz

max. temp.(℃):1200(1 hour)

working temp.(℃):1100

heating rate(℃/min):≤50

tube size(mm):

Φ50×1200mm

heating zone length(mm):440mm

(mm):200mm

temp. control:l PID automatic control and auto-tune function.

l 30 programmable segments for precise thermal processing. l Built-in protection for the over-heated and broken thermocouple.

Temperature Accuracy(℃):±1

Heating Element:Resistance wire, Fe-Cr-Al Alloy doped by Mo

|

|

gas supply system,GMF3Z

|

(MFC)

weight:35Kg

overall size:600x600x650mm

Standard range(N2):50sccm、200sccm、500sccm; (optional)

Accuracy:±1.5%

|

|

vacuum unit,VAU-02

|

pumping rate:4L\s

ultiamte vacuum:5X10-1Pa

oil capacity:1.1L

Rotation rate:1450rpm

noise:50dB

overall size:600×600×600mm

|